The School of Mechanical Engineering of USST (University of Shanghai for Science and Technology) was founded in May of 1999. It was formed by the merger of the former Mechanical Engineering Department on USST campus and Mechanical Engineering Department on Fuxing Road campus. The history of the school can be traced back to 1912 when Electromechanical Engineering College of Deutsche Medizinschule was created. After nearly 90 years of development, School of Mechanical Engineering has become a dominant national training base for advance manufacturing professionals and the scientific research provision of advanced manufacturing technology in Shanghai.

The school is doctoral degree-awarding body and master’s degree-awarding body for class-A disciplines in mechanical engineering covering five class-B disciplines, i.e., Mechanical Manufacturing and Automation, Mechanical Design and Theory, Mechatronic Engineering and Automotive Engineering, Electrical Engineering. Undergraduate programs include: Mechanical design, Manufacture & Automation; Automotive Engineering; Electrical Engineering & Automation; Mechanical Design, Manufacture & Automation (international engineering) (Sino-German program). The master’s degree program in Mechanical Manufacturing & Automation is designated as key program by Shanghai Municipal Education Commission. The undergraduate program in Mechanical Design, Manufacture & Automation is designated as special program by the national Ministry of Education.

The school has a faculty team which is dynamic, excellent in teaching style and balanced in member composition. Among 180 faculty members and more, including 20 professors, 67 associated professors, there are members of national “tens of millions of talents project”, national model teachers, Shanghai famous teachers, etc.

With a long history of 100 years, USST has been acclaimed as the “cradle of engineers for manufacturing industry” as its mechanical manufacturing program which has exerted major influence on higher engineering education history of China. Adopting the strategy of “giving priority to the development of advanced manufacturing industry” of Shanghai and relying on the advantages from the University’s former attachment to Ministry of Machine Building as well as one of the six discipline groups of the University, i.e. “advanced manufacturing and equipment technology discipline group”, the School carries forward the cause pioneered by its predecessors and forges ahead into the future.

The school now has five undergraduate programs, i.e., mechanical design, manufacture & automation; automotive engineering; electrical engineering & automation; robot engineering; mechanical design, manufacture & automation (international engineering) (Sino-German cooperation).

Prize for "Innovation and Entrepreneurship Competition" presented to ME students

University of Shanghai for Science and Technology had been accredited to issue master’s degree for Mechanical Design and Theory as early as in 1984; Mechanical Manufacture and Automation in 1986; Mechatronic Engineering in 1996; as well as Mechanical Engineering discipline (first level) in 2006, covering four second level disciplines: Mechanical Manufacture and Automation, Mechanical Design and Theory, Mechatronic Engineering, Automotive Engineering. The professional master’s degree programs for Mechanical Engineering and Automotive Engineering were accredited in 1998 and 2009 respectively.

Mechanical Manufacturing and Automation Specialty: 1) CAD/CAM; 2) NC technology; 3) Modern materials processing technology; 4) Advanced manufacturing technology; 5) Automatic equipment and system.

Mechatronic Engineering Specialty: 1) Precise measuring technology; 2) Mechanical control engineering; 3) Electromechanical integration; 4) Mechanical fault detection and diagnosis; 5) Intelligent control.

Mechanical Design and Theory Specialty: 1) Application of modern design in mechanical design; 2) Dynamic design and simulation of machine system; 3) Mechanical transmission design theory; 4) Robot and artificial intelligence; 5) Ergonomics.

Automotive Engineering Specialty: 1) Automotive modern design theory; 2) Automotive electronic control technology; 3) Auto detection and fault diagnosis; 4) Vehicle power system and matching techniques; 5) Vehicle dynamics simulation.

Mechanical Engineering Specialty (Professional Degree): 1) Precision measurement and intelligent control; 2) NC technology; 3) CAE technology and application.

Vehicle Engineering Specialty (Professional Degree): 1) Design of modern automotive components; 2) Development of automotive electronic control system; 3) Auto parts recycling technology.

In 2011, the school was accredited to grant doctoral degree for Mechanical Engineering (first level discipline). The doctoral programs focus on major theoretical and practical issues in areas of advanced manufacture and modern automotive technology.

Double Doctoral Degree with Coventry University

Double Bachelor Degree with Germany Furtwangen Hochschule

Double Master Degree with Germany Kaiserslauten Hochschule

The main research areas are:

1) Precision Engineering and Associated Manufacturing Technology

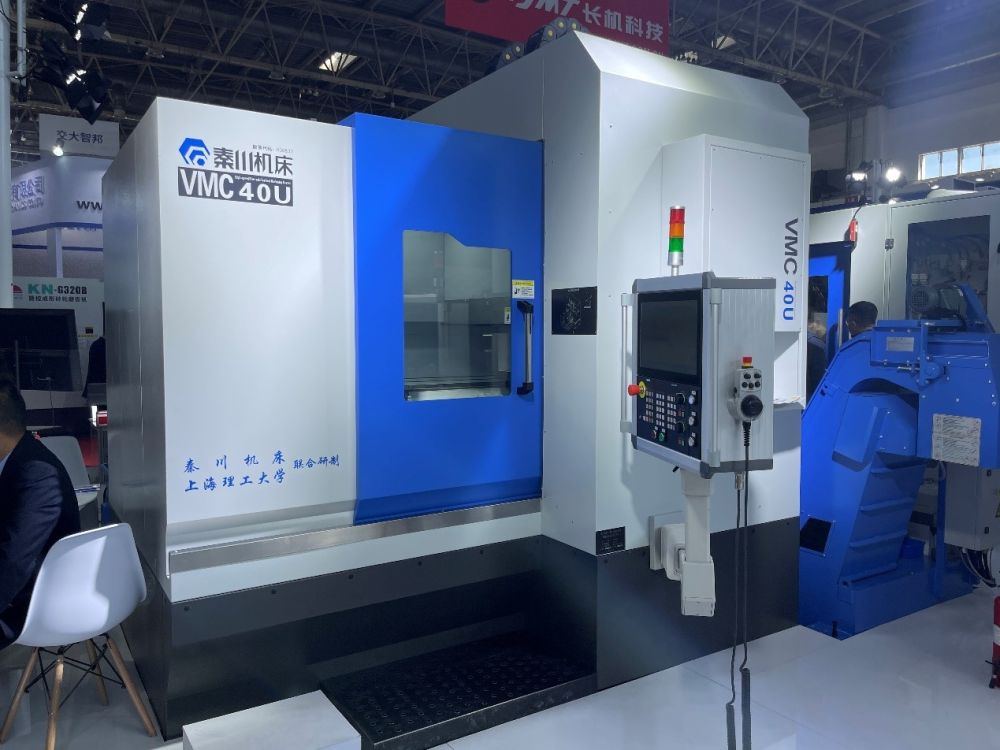

Past participation in more than twenty national or municipal key projects enables the school to establish advanced principles, master various key technologies in areas such as: precision/ultra-precision NC grinding technology research; optimization theory of grinding process parameters based on acoustic emission. These achievements leads to the development of a research platform for precision NC grinding technology, which includes equipments such as NC cylindrical grinder; NC surface grinder; NC profile grinder and a detection system for dynamic grinding performance. The school research effort and ability is highly acclaimed in the NC machine tools industry. Our university has conducted technical cooperations with Shanghai Machine Tool Co., Ltd.; Shenyang Machine Tool (Group) Co., Ltd.; Qinchuan Machine Tool Group Co., Ltd.; Beijing Machine Tool Institute. Also we have started co-operation with the Machine Tool Research Institute of Stuttgart University in Germany.

2) Advanced Design Theories and Methods of Mechanical Equipments

This program focuses on multidisciplinary design optimization method, virtual design technology, digital analysis synthesis technology of mechatronic equipment, and design methodology of the special purpose NC equipments. By studying the adaptive growth mechanism of natural systems and structures, such as the morphology of biological branching networks and the bone tissues, an innovative structural topology design optimization method has been suggested. The method has been applied to the rib layout design of plate and shell structures, as well as topology optimization design of truss and three-dimensional solid structure. Further this program systematically research into overall multi-body dynamics simulation technology of complex mechatronic equipment; optimization design of machine tool structure; precision retention ability and heat balancing; cutting dynamics and cutting stiffness of machine tools. These researches are applied to high-grade special purpose NC equipment design.

3) Vehicle Parts Design and Optimization Program

This program focuses on automobile core structural components development and design processes. The research activities include the core technology chain of design principles and process evaluation of self-development process of automotive structural components. It brings forward lightweight design method that matches operating stress interval with low-load strengthening interval of the related component structure, resulting low-cost lightweight design theory based on maximization of low-load hardening features to ensure the optimization of components strength potential. The results of these researches lead to break through of traditional design and optimization method which relies on safety factor strengthening design principles. Its distinctive characteristics and social implications coincide and match the national long-term development plan of enhancing national automotive performance for lower emission and energy conservation. In its own way the program contributes positively to national economy and brings benefits to the society.

4) Non-traditional Processing Technology

This research program includes: development and application of "super-hard" surface coating technology for precision cutting tools manufacture; medical β titanium surface processing technology; cold/hot working of high-strength copper belts; relation between mechanism and performance of compound enhancement as well as high-precision copper processing technology. In area of measurement technology, the program carries on researches on measurement and control of plate and residual stress.

5) Advanced Manufacturing System and Management

It focuses on enterprise supply network and its management, advanced manufacturing system management, network-based manufacturing and its key technologies, manufacturing execution system as well as product data management. In the context of environment of network manufacturing, considering the pattern of enterprise manufacturing systems, a set of manufacturing system pattern—Multi-functional, Open Enterprise Supply and Demand Network has been proposed. It also refers to theories, methods and tools of manufacturing enterprise knowledge engineering. The research results have been applied to dynamic alliance management of regional network-based manufacture. The results can also be used in production plan and dispatch for mass customization production, mechanical design knowledge management, development of rapid mechanical design platforms, etc.

High-speed Vertical Five-Axis Maching Center VMC40U

Home

·

News & Events

·

Content

Home

·

News & Events

·

Content