Dr. Chen Aiying is an outstanding teacher from USST, who has achieved a lot in her research field in recent years. Her research fields can be briefly classified into three directions, which are: design & preparation of advanced steels with high strength & high ductility, strengthening mechanisms of nanostructured steels and surface functionalization of metallic materials. To get more acquainted with Prof. Chen, there has been an interview with her, which helps us to learn more about her contributions to nanostructured steels.

Nanotwins (NT) are coherent crystalline structures inside grains, characterized by mirror-symmetrical interfaces. This special defect structure is considered to be a desirable structure for overcoming the traditional dilemma between strength and ductility. However, the strength-ductility synergism of the NT-ed materials are controlled by very complicated behaviors, influenced by multiscale diversities of NTs and complex deformation characters. Besides these difficulties, the NTs in the structural steels, commonly produced by severe plastic deformation (SPD), are deformation NTs that exhibit a high density of defective structures. However, the effects of defective TBs on the deformation behaviors are less understood in nanotwin-strengthened materials. Furthermore, martensitic transformation is the most likely deformation mode in NT-ed austenitic steels because of the metastable austenite phase. Hence, it is difficult to observe or predict the deformation evolution due to indistinguishable structures in postmortem observations or the multiscale diversities in simulations.

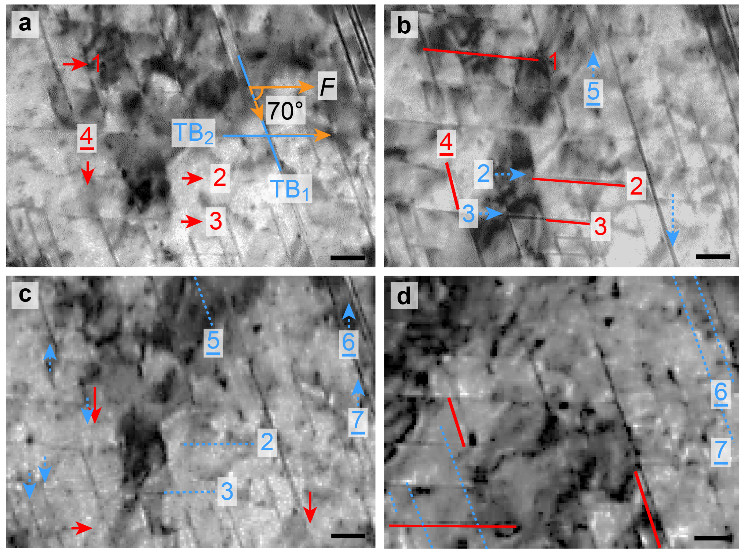

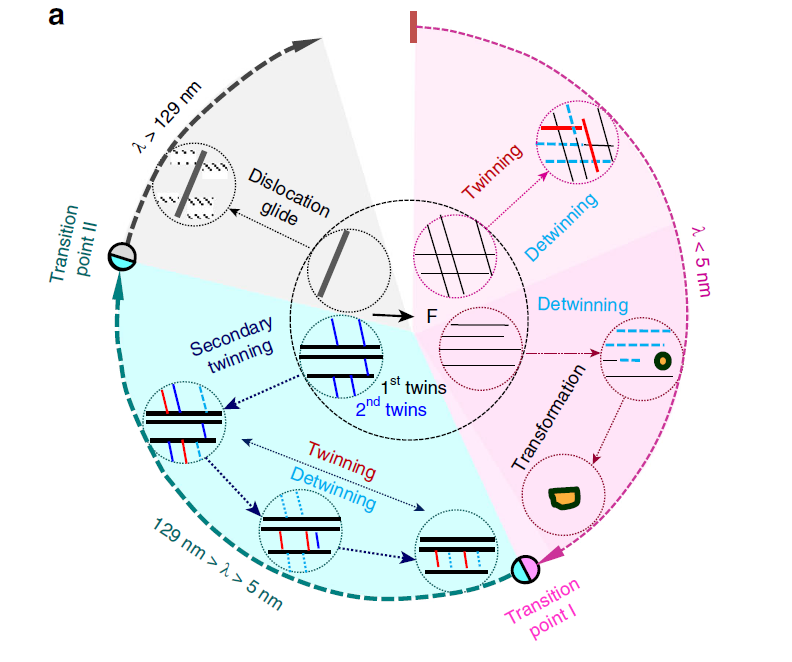

In her work, she investigated the twin-lamellar-spacing (λ)-dependent effect on the deformation transitions of NT-ed steels. She performed in situ transmission electron microcopy (TEM) tensile tests to obtain direct evidence of the deformation characteristics, applied a dislocation-based theoretical model and conducted molecular dynamics (MD) simulations to reveal the deformation transition mechanisms of NTs. Both the in situ tests and the simulation results show that there are two critical λs to transit the deformation mode from twinning/detwinning to secondary twinning, and then to dislocation accumulation. She generated a deformation map of NTs as a function of λ, which may aid in the design of advanced steels with superior strength-ductility synergy.

Firstly, she in-situ observed the deformation transition mechanisms of NTs with different scales. When λ is smaller than 5 nm, the twinning and detwinning are jointly activated under shear stress and detwinning and martensitic transformation occur successively when the TBs are closely parallel to the loading direction. When λ is 6 to 129 nm, secondary twinning is induced inside the primary twin system, and the twinning and detwinning are coactivated only in the secondary twin system. As λ increases to the submicrometer scale, dislocation motion is the featured deformation behavior, as observed in TEM tensile tests.

Secondly, she constructed a deformation pattern of multiscale NTs, which provides a clear strengthening mechanism for microstructure manipulation. In contrast to the conventional dislocation strengthening in CGs, the twinning, including the secondary twinning, can simultaneously enhance the strength by dislocation pile-up at the TBs and improve the ductility due to partials slipping across TBs. The detwinning softens the material by decreasing the TBs, which is similar to the effect of grain growth. Thus, the coactivation of twinning and detwinning can sustain successive hardening during plastic deformation. This is a special deformation behavior of NTs on the very fine scale. Accompanied by the detwinning, martensitic transformation is initiated earlier than the other coarse austenite grains, which can further strengthen the materials.

Finally, she developed a dislocation-based theoretical model and MD simulations to reveal why there is a confined range to initiate secondary twinning. The intrinsic mechanisms to trigger twinning/detwinning were elucidated by considering two active partials of 60° and screw systems. A series of MD simulations was carried out to investigate the deformation transition mechanisms. The partial dislocation of the 60° system is primarily responsible for the detwinning, whereas the screw system exhibits twinning deformation. Detwinning is dominant when the TB orientation is closely parallel to the tensile direction.

A Brief Introduction of Prof. Chen

Aiying Chen is a Doctor, a Professor and a Doctoral Supervisor at the School of Materials Science and Engineering, University of Shanghai for Science and Technology. In the past five years, she has published more than 30 SCI articles (5 JCR Q1 papers) and chaired three projects of the National Natural Science Foundation of China. Her research fields include: (1) Design and preparation of advanced steels with high strength and high ductility; (2) Strengthening mechanisms of nanostructured steels; (3) Surface functionalization of metallic materials.