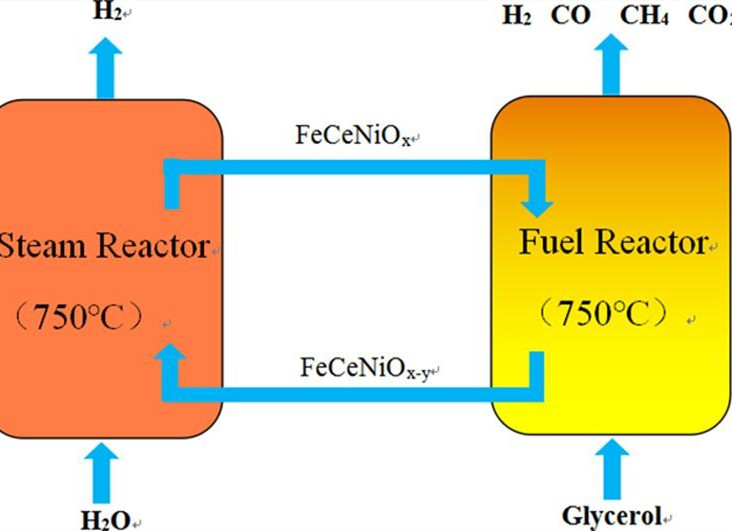

Recently, the research team led by Prof. Dou Binlin successfully made porous Fe oxygen carrier throughsol-gel, by enhancing the interplay between carriers and loaded Fe-Ce-Ni metal particles to improve its activity and stability, and having achieved chemical looping 750℃ direct water splitting for hydrogen production, and simultaneously decomposed bio-glycerol to produce syngas.

The research developed high-performance and economical porous Fe oxygen carrier, having revealed the function mechanism between the carriers and the loaded metal particles, and proposed a new chemical looping method of redox for water splitting hydrogen production, and coupling catalysis decomposition for syngas production.

The research achievement was published in Energy Conversion and Management entitled “Co-production of hydrogen and syngas from chemical looping water splitting coupled with decomposition of glycerol using Fe-Ce-Ni based oxygen carriers”. (Division 1 of Chinese Academy of Science, SCI impact factor 8.208), the first author of which is a postgraduate student named Chuanqi Luo from the School of Energy and Power Engineering, and he was granted by National Natural Science Foundation and Science and Technology Commission of Shanghai Municipality program.

China’s 3060 Carbon-peak and Carbon-neutral Strategy aims to accelerate the rapid development of hydrogen energy, and hydrogen energy has attracted the attention and investment all over theworld. Up to early2021, more than 30 countries has issued the roadmap of hydrogen energy, and over 200 hydrogen energy projects and ambitious development plans had been announced by the industry circle. In order to develop hydrogen energy, the research and development of sustainable hydrogen production methods that aim at the disuse of fossil fuel consumption and zero emission of CO2 should be given priority to.

Water has richer hydrogen than any other substance in nature. However, direct water splitting requires extremely high temperature and absorbs large amount of heat in this process, which is of high cost and energy consumption.

Using oxygen carrier chemical looping for direct water splitting can lower the temperature, the oxygen decomposed by water can get involved in the oxygen carrier’s oxidation reaction without hot gas separation. If it can be decomposed by biomass to produce syngas, then this way can serve as a potential economical method for syngas and hydrogen production that can be applied in a large scale and achieve zero emission of greenhouse gases. Besides, the main research direction in this stage is exploring the oxygen carrier oxide system that can split water in a relatively low temperature.